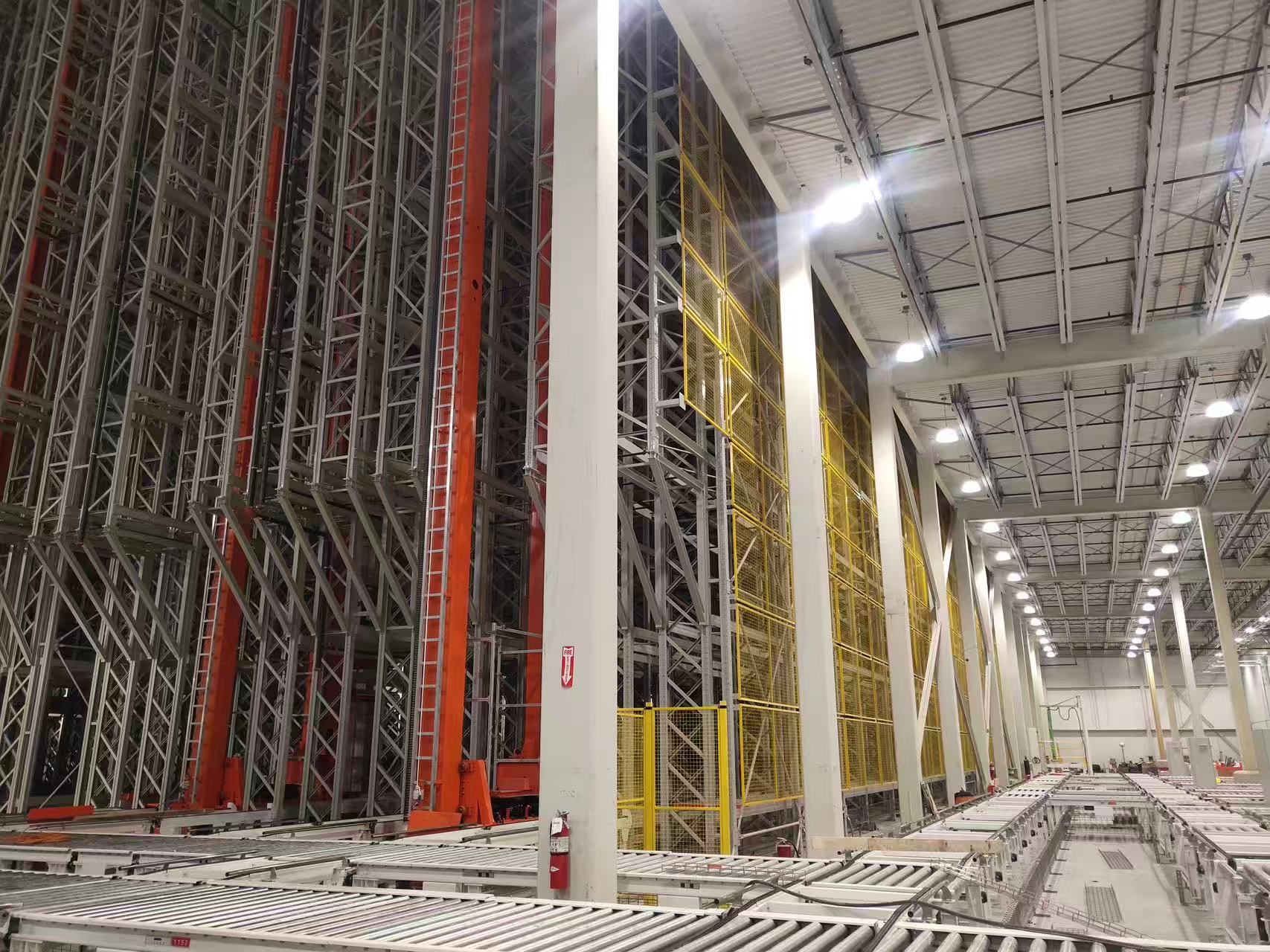

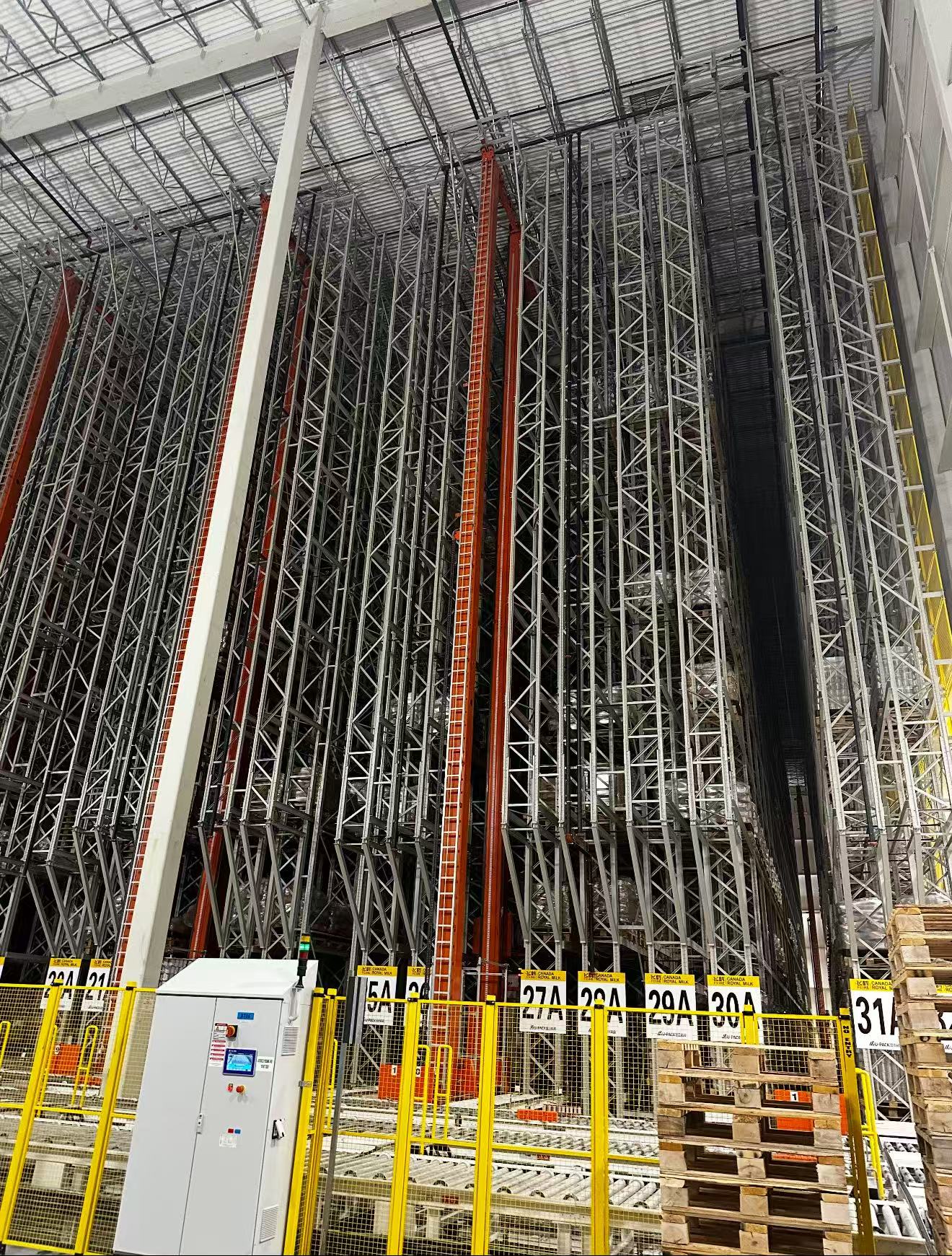

INNO begins with precision warehouse racking installation, combining engineered steel frames, shelving profiles, and aisle numbering to maximize space while ensuring structural safety. Our electrical work team then coordinates high- and low-voltage distribution, lighting, backup power, and grounding so every zone remains energized and code compliant.

When we move into automated rack implementation, sensors, stacker cranes, shuttles, and conveyors are calibrated to the layout, and we stitch control cabinets into a resilient PLC/SCADA ecosystem. The resulting automated control system orchestrates inbound, storage, picking, and outbound tasks with visibility in real time.